| Technical Talk -> How to ... step by step. | Correctly Adjusting Hagon 3... - Draining the fuel tank | | [1],[2],[3],...,[5],[6],[7],[All] - Next page | | | Categories : |

|  | Topic : FITTING AFTERMARKET REAR WHEEL ADJUSTERS. |  |

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

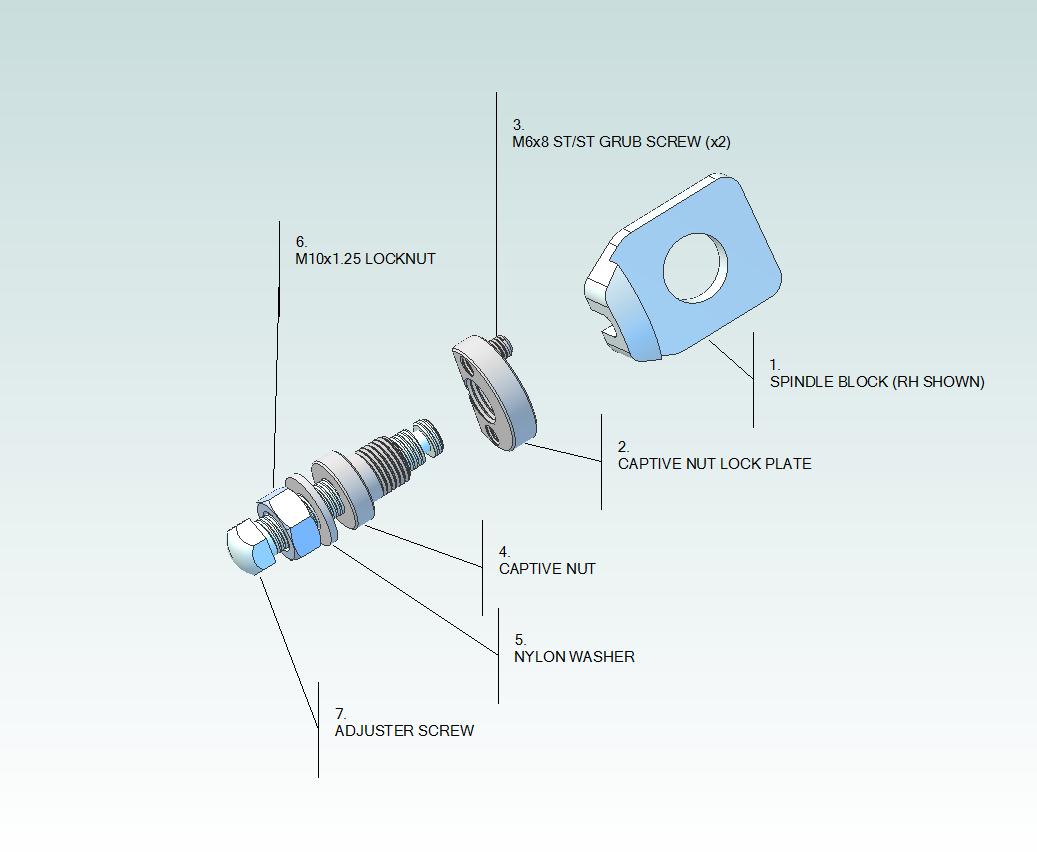

| | Posted : 18 Aug 2012 - 15:49 Post title : FITTING AFTERMARKET REAR WHEEL ADJUSTERS. | | | I was going to put a set of fitting instructions in each pack but thought it would be better to post it on here.

The adjusters are sent as an assembled unit, how it will be on the bike. Apart from a nylon washer(5) (afterthought) which should go between the captive nut(4) and locknut(6).

Dissasemble the unit and fit the nylon washer(5) and replace the captive nut(4) leaving the captive nut lock plate(2) loose.

Jack up the bike as you would normally with the back wheel just touching the floor. Undo the main nut and the standard adjusters and draw out the spindle. Remove the standard adjusters and store them.

Slide the LH spindle block(1 LH) onto the spindle so that it mates with the flats. Replace the spindle so far (to save spacers etc. dropping out).

Hold the captive nut lock plate(2) at the back of the adjuster hole in the swing arm and screw in the rest of the adjuster screw assembly from the rear. Leave a small gap between the swing arm and captive nut lock plate(2), the unit will appear slack, then tighten the grub screws(3).

Screw the adjuster screw(1) fully in and then slide the spindle block(1) onto the groove on the end of the adjuster screw(1).

NOTE. By pushing the spindle block(1) up against the swing arm there should be very little or no bending of the adjuster screw(1).

If there is slight inward force on the adjuster screw(1) then slacken the grub screws(3) slide the unit towards the

wheel and re-tighten.

Give the grub screws a good tighten - thread lock can be used on the grub screws(3) and the captive nut lock plate(2). On the next wheel change or belt tension check to make sure the captive parts are tight.

Once you have set the captive nut assemblies on both sides of the bike then reassemble the bike as normal - making sure both spindle blocks (1RH & 1LH) are in the adjuster slots.

TO ADJUST THE WHEEL

Slacken the locknuts(6) . Slacken the main spindle nut, the main nut can be partially tight (hand tight) to use the adjusters.

Adjust the belt tension first (RH) and then the left side to align the wheel - once you are happy then tighten the main spindle nut (110Nm) and very slightly tighten the two lock nuts(6) on the adjusters.

NOTE> The adjusters do NOT need a locknut, I have put one on to simply take out any vibrations and rattles (like we need some

more). Because of the tight space to get this unit in on the swing arm, I found that if the locknut(6) is very tight on to the

face of the captive nut(4) it slackens when undoing the locknut. The nylon washer is used to allow the locknut to be

secured suitably.

The adjusters CAN be operated with the bike on it's side stand.

CARE OF THE PRODUCT

The coatings on the adjusters is just that, a coating. Where mating parts touch and rub (like threads) then there is allways the possibility of the coating wearing thin. On a product like this it is unavoidable. I have spent a good time talking with the platers and getting the best result - the black adjusters are actually three times more expensive to coat as I opted for a top quality chemical process to get a better result on the blacks.

Therefore, rust preventatives are recommended and/or lubrication to ensure a long working life. Afterall, this is a precision made part that is placed on the butt end of the bike and will recieve all the worst kind of debris.

Hope I have covered everything. Chris (Cornerbanger) has some pics he took of the fitting which will be posted here.

| My first natural instinct is to breathe. My second is to evade tax's.

| | Post edited by mat1600 on 18 Aug 2012 - 16:06 |

|

| | | CornerBanger | | Jupiter |  |  | | Reg. Date | : | 07/07/2010 | | Posts | : | 1,113 | | Location | : | Charleston, SC, United States |

|

| | Posted : 20 Aug 2012 - 01:08 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | | As promised, here are pictures to aid Mat's instructions. The pictures are in sequential order to follow his instructions. Further, the original thread of the adjusters being vetted and the accompanied pictures are referenced for additional help. Link

| There are those who own and there are those who ride!

2010 Thunderbird

2007 Kawi KX250F

2010 Kawi KX85 (My boy's ride)

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 20 Aug 2012 - 19:17 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: CornerBanger) | | | So can i assume that when you screw the 2 round parts together thru the arm hole you then use the 2 small allen head screws on the inner part to lock them in place?

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 20 Aug 2012 - 19:34 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

So can i assume that when you screw the 2 round parts together thru the arm hole you then use the 2 small allen head screws on the inner part to lock them in place? |

|

Yes. The reason fro the small gap is because that back face is not a machined face, so the grub screws are used to A. Hold the captive nut square to the outer face B. Hold the captive nut tight so that it doesn't turn.

This was a bit of a problem to overcome without useing a more permanent method ie. a rivet type of application - which would have meant the use of a tool to fit and secure it.

The captive nut locking plate will benefit from a drop of thread lock if you ever get the chance . (making sure you dont get it on the adjuster screw) The Triumph dealers have it in. I would have liked to supply a small sachet of the stuff, but couldn't find any small enough.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 20 Aug 2012 - 20:02 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | | i have thread locker. I think most do, and it's cheap anyways.

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 21 Aug 2012 - 16:28 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. | | | Just thought of a question after looking at your pics again CB....in the second to last pic it shows the inner round piece flush against the arm. In the last pic it shows it backed away from the arm a bit and the allen screws holding it there. Can i assume you first put it flush then later realized that when you went to put the part on the spindle goes thru that with the round part was flush it caused the threaded part to arrive at the spindle part too far up or down to set in the groove for it ? Then loosened it, set the spindle part in place then tightened the 2 allens while the round part was being forced into the correct angle by the threaded part as it sat in the spindle part ? Wow....hope that made sense, as it's hard to describe shit like this in text !

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 21 Aug 2012 - 17:32 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | | If you read the instructions it explains all that. The grub screws pull the captive nut tight against the outer face of the swing arm. Also, the inner face is not square to the outer machined face (where the standard adjuster nut would seat) so the two screws pull the captive nut square and tight If the captive nut were to tighten into the captive nut lock plate it would 'cockle' to a side, which in turn would leave the adjuster screw going thru at an angle.

I hope that made sense. Its one of those things you will understand when you get them in your hands and see how they fit.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

| | | CornerBanger | | Jupiter |  |  | | Reg. Date | : | 07/07/2010 | | Posts | : | 1,113 | | Location | : | Charleston, SC, United States |

|

| | Posted : 21 Aug 2012 - 17:39 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

Just thought of a question after looking at your pics again CB....in the second to last pic it shows the inner round piece flush against the arm. In the last pic it shows it backed away from the arm a bit and the allen screws holding it there. Can i assume you first put it flush then later realized that when you went to put the part on the spindle goes thru that with the round part was flush it caused the threaded part to arrive at the spindle part too far up or down to set in the groove for it ? Then loosened it, set the spindle part in place then tightened the 2 allens while the round part was being forced into the correct angle by the threaded part as it sat in the spindle part ? Wow....hope that made sense, as it's hard to describe shit like this in text ! |

|

First, lets use Mat's drawing to reference thingy's, round parts, that part, inner round parts, etc. to part numbers and names...

No. I first mounted the Captive Nut (4) and the Captive Nut Lock Plate (2) onto the swingarm tab and threaded the two pieces together to their stop. Once together they will still move inside the tab because Mat designed them not to be totally tight due to the imperfection of the swingarm's machined surface (it is the Grub Screw/s (3) purpose to take out the slack). With the the Captive Nut (4) and the Captive Nut Lock Plate (2) slack you finish assembling the adjuster. Once the adjuster is assembled you slide the axle through it to provide the correct alignment. Finally, you tighten the Grub Screws (3) to hold the Captive Nut (4) and the Captive Nut Lock Plate (2) in place against the swingarm tab providing the correct alignment. Once this is done you will never (almost) have to do it again.

| There are those who own and there are those who ride!

2010 Thunderbird

2007 Kawi KX250F

2010 Kawi KX85 (My boy's ride)

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 21 Aug 2012 - 19:26 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: CornerBanger) | | | I guess i wasn't clear, but I think you basically described what i said except that you suggest a different reason for doing it that way. To understand better, in the second to last pic where the captive lock nut plate is fully tightened against the arm, why didn't you just tighten the 2 allens at that point? I assume you didn't do that because in that pic both the captive nut and CN lockplate are both fully against the arm. In the last pic theres quite a sizable gap between the CNLP and the arm. I understand that you're saying the mating surface of the CNLP and arm are not perfect, but why would that not allow you to leave it fully seated and THEN tighten the allens instead of backing the CNLP a few turns first.

You know, it's probably not worth discussing because i could tell you in a conversation exactly what i'm trying to ask, but in type i'm just getting frustrated trying to make a point that i seem to need 10 pages of text to explain yet in voice could do so in a minute. No big deal. When i get them I know what to do, or will as soon as i start installing.

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | CornerBanger | | Jupiter |  |  | | Reg. Date | : | 07/07/2010 | | Posts | : | 1,113 | | Location | : | Charleston, SC, United States |

|

| | Posted : 21 Aug 2012 - 19:36 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | | Daz,

The picture's glare is fooling your eye into believing the CNLP and the CN are fully seated against the tab. They are not. I could move them with my fingers until i tightened them with the grub screws. I am a computer guy not a photographer...

| There are those who own and there are those who ride!

2010 Thunderbird

2007 Kawi KX250F

2010 Kawi KX85 (My boy's ride)

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 21 Aug 2012 - 19:58 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: CornerBanger) | | | Weird. Looks pretty clear to me. I see a gap in one pic and none in the other, and since those two parts screw together i can't understand how tightening the allens would cause that gap. But no matter.....just curious.

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | weasel | | Set |  | | Reg. Date | : | 14/02/2012 | | Posts | : | 150 | | Location | : | Thornbury,Bristol, South Gloucestershire, United Kingdom |

|

| | Posted : 21 Aug 2012 - 20:01 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | | just received my adjusters very professional , cheers mat , will get them fitted as soon as pos

|

ride till your tyres fall off

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 21 Aug 2012 - 20:17 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

Weird. Looks pretty clear to me. I see a gap in one pic and none in the other, and since those two parts screw together i can't understand how tightening the allens would cause that gap. But no matter.....just curious. |

|

I see what you mean. Actually the swing arm is recessed at the back (facing) face so it could be that the captive nut( in this pic) is not up against its face. The inner face is not a lot out of square but enough to need the screws.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 21 Aug 2012 - 20:27 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | | I get what you're saying Mat. It does look like in the second pic it might be slightly thinner which would speak to that. Tho it doesn't seem to have sunk in to the same amount as the gap on the CNLP side. But I'll assume like he said it's the pics. The one IS a bit blurry and the pic sizes are different.

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | CornerBanger | | Jupiter |  |  | | Reg. Date | : | 07/07/2010 | | Posts | : | 1,113 | | Location | : | Charleston, SC, United States |

|

| | Posted : 21 Aug 2012 - 22:03 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

Weird. Looks pretty clear to me. I see a gap in one pic and none in the other, and since those two parts screw together i can't understand how tightening the allens would cause that gap. But no matter.....just curious. |

|

I can't explain it in any other way. Wait for the adjusters and mount them and report back. Maybe you can articulate it in words better than I.

| There are those who own and there are those who ride!

2010 Thunderbird

2007 Kawi KX250F

2010 Kawi KX85 (My boy's ride)

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 22 Aug 2012 - 20:29 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: CornerBanger) | | | Well, i broke down and bought mat's adjusters the other day, so i figured screw it.....may as well go all the way so i ordered the tool too. At not too far from $200 for both, this better be the end of all this belt BS !!!!!

One thing i discovered just in the last few days is the belt runs quiet only when resting slightly against the outer flange. Theres a slight gap there but being that the flange is tapered, the bottom of the teeth are probably just touching. And thats the way it was after micky adjusted the warranty belt last year with the same tool we are buying. So i'm thinking when we adjust it with the tool thats probably where it will run and is likely the correct place for it. I just hope this is the end of the belt alignment fiasco !

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 30 Aug 2012 - 23:33 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | | Got em today Mat....very nice. They look better than the pics. By the way, is the nylon just for avoiding coating wear between the locknut and captive nut?

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 31 Aug 2012 - 07:14 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | | Yes and it means you dont have to tighten the locknut up so much. It doesn't need a locknut its just there to stop things vibrating. For future ones it may even be just a plastic nut - when I can find one that doesn't look cheap and crap.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

| | | Leethal | | Zeus |  |  | | Reg. Date | : | 24/01/2011 | | Posts | : | 6,548 | | Location | : | Australia |

|

| | Posted : 31 Aug 2012 - 07:51 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | | Finally got my new spindle today  , so hopefully find time over the weekend to fit all the gear. , so hopefully find time over the weekend to fit all the gear.

| Experience is something you get just after you needed it

1600,Foran Razorbacks, Meerkat bypass, Dyno tune, real headlight,plenty of chrome,switchblade pegs, Nitron R3 shocks & Ikon progressive fork springs etc. Scorpion Western Low handlebars. PH adjustable fork caps.

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 31 Aug 2012 - 13:44 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | |

mat1600 wrote:

Yes and it means you dont have to tighten the locknut up so much. It doesn't need a locknut its just there to stop things vibrating. For future ones it may even be just a plastic nut - when I can find one that doesn't look cheap and crap.

|

|

Naaa ! Thats would be cheezy. The washer looks a lot better than a plastic nut, which also would get nasty and maybe even crack over time. Don't go all honda on us now Mat !

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | ezrider3 | | Chaac |  |  | | Reg. Date | : | 21/01/2010 | | Posts | : | 505 | | Location | : | Maryland, United States |

|

| | Posted : 31 Aug 2012 - 20:06 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: mat1600) | | | So, where's mine and how much?

|

|

| | | Druid | | Jupiter |  |  | | Reg. Date | : | 14/10/2009 | | Posts | : | 1,359 | | Location | : | United Kingdom |

|

| | Posted : 01 Sep 2012 - 16:12 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: ezrider3) | | | Fitted and on. New tires on the bike and the service man said the new bits were very nice .

Cheers matt.

| Socialism is the philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery - W.Churchill

|

|

| | | daz | | Zeus |  |  | | Reg. Date | : | 12/05/2009 | | Posts | : | 7,719 | | Location | : | United States |

|

| | Posted : 01 Sep 2012 - 21:53 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: Druid) | | | Just installed mine today. One thought Mat....why not hex captive nut instead of round? It woulda been much easier to install on mine at least. they're certainly nice tho, and adjustment is soo much simpler and accureate. Unfortunately after god knows how many tightenings to 110 Nm on the spindle nut screwing with the fucking belt forever, the threads gave up the ghost when i tightened it back up. So no riding for me till i receive my new HUNDRED AND TWENTY TWO FUCKING DOLLAR SPINDLE !!!! ($111+$11 nut)

| 2010 Blue/White Thunderbird, "Brutus". 1700 kit, short tors, gutted cat, UNI filter, filter seal off, custom tune. Brutus in his native habitat: Link

|

|

| | | mjgt | | Thor |  |  | | Reg. Date | : | 16/09/2011 | | Posts | : | 2,201 | | Location | : | North Somerset, United Kingdom |

|

| | Posted : 02 Sep 2012 - 07:03 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

Just installed mine today. One thought Mat....why not hex captive nut instead of round? It woulda been much easier to install on mine at least. they're certainly nice tho, and adjustment is soo much simpler and accureate. Unfortunately after god knows how many tightenings to 110 Nm on the spindle nut screwing with the fucking belt forever, the threads gave up the ghost when i tightened it back up. So no riding for me till i receive my new HUNDRED AND TWENTY TWO FUCKING DOLLAR SPINDLE !!!! ($111+$11 nut)   |

|

Wow, thats an expensive bolt, must have been hand made by a virgin

| Mick . . .  Keep the rubber side down!! Keep the rubber side down!!

|

|

| | | Leethal | | Zeus |  |  | | Reg. Date | : | 24/01/2011 | | Posts | : | 6,548 | | Location | : | Australia |

|

| | Posted : 02 Sep 2012 - 09:03 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

Just installed mine today. One thought Mat....why not hex captive nut instead of round? It woulda been much easier to install on mine at least. they're certainly nice tho, and adjustment is soo much simpler and accureate. Unfortunately after god knows how many tightenings to 110 Nm on the spindle nut screwing with the fucking belt forever, the threads gave up the ghost when i tightened it back up. So no riding for me till i receive my new HUNDRED AND TWENTY TWO FUCKING DOLLAR SPINDLE !!!! ($111+$11 nut)   |

|

Join the club Daz, I had to wait six weeks for my spindle as Triumph were out of stock. I got away with cleaning up the thread with a die and buying a full size locknut which covers more thread. That lasted till I fitted my new stuff today.

| Experience is something you get just after you needed it

1600,Foran Razorbacks, Meerkat bypass, Dyno tune, real headlight,plenty of chrome,switchblade pegs, Nitron R3 shocks & Ikon progressive fork springs etc. Scorpion Western Low handlebars. PH adjustable fork caps.

|

|

| | | Sensiblepete | | Set |  |  | | Reg. Date | : | 20/08/2011 | | Posts | : | 158 | | Location | : | Sweden |

|

| | Posted : 02 Sep 2012 - 09:17 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: Leethal) | | | Small engineering question?

All things being equal; with clean threads, and properly lubricated, is there a finite life on a bolt/nut thread arrangement when using the proper torque?

Or will they fail/shear after a being torqued so many times?

|

|

| | | mjgt | | Thor |  |  | | Reg. Date | : | 16/09/2011 | | Posts | : | 2,201 | | Location | : | North Somerset, United Kingdom |

|

| | Posted : 02 Sep 2012 - 10:08 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: Sensiblepete) | | | They will wear but SHOULD last the life of the bike in NORMAL use. Now all you need to know is what is normal and how long the bike is going to last.

| Mick . . .  Keep the rubber side down!! Keep the rubber side down!!

|

|

| | | Leethal | | Zeus |  |  | | Reg. Date | : | 24/01/2011 | | Posts | : | 6,548 | | Location | : | Australia |

|

| | Posted : 02 Sep 2012 - 11:43 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: Sensiblepete) | | |

Sensiblepete wrote:

Small engineering question?

All things being equal; with clean threads, and properly lubricated, is there a finite life on a bolt/nut thread arrangement when using the proper torque?

Or will they fail/shear after a being torqued so many times?

|

|

Well they have failed, so yes is the answer. Depends I guess on how many times that nut is torqued, personally the spindle looks a bit light on for me and the nut is a half nut, so 110nm spread over about six threads.

| Experience is something you get just after you needed it

1600,Foran Razorbacks, Meerkat bypass, Dyno tune, real headlight,plenty of chrome,switchblade pegs, Nitron R3 shocks & Ikon progressive fork springs etc. Scorpion Western Low handlebars. PH adjustable fork caps.

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 02 Sep 2012 - 12:05 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: daz) | | |

daz wrote:

Just installed mine today. One thought Mat....why not hex captive nut instead of round? It woulda been much easier to install on mine at least. they're certainly nice tho, and adjustment is soo much simpler and accureate. Unfortunately after god knows how many tightenings to 110 Nm on the spindle nut screwing with the fucking belt forever, the threads gave up the ghost when i tightened it back up. So no riding for me till i receive my new HUNDRED AND TWENTY TWO FUCKING DOLLAR SPINDLE !!!! ($111+$11 nut)   |

|

Shit -sorry to hear that.

Like Lee, I too think the spindle is a bit on the light side and that fine thread can soon get 7ucked up.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 02 Sep 2012 - 12:39 Post title : Re: FITTING AFTERMARKET REAR WHEEL ADJUSTERS. (Re: ezrider3) | | |

ezrider3 wrote:

So, where's mine and how much?

|

|

PM sent.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

|

| |

| |

|